Silicone rubber cable

As a 20 years old Medical cable manufacturer,we have helped medical industry partners to develop more than 1000 types of cables.Among all the cables we made,Silicone rubber cable ranks 2nd. (TPU cable rank 1st),it is very significant to make an comprehensive introduction to Silicone cable.

In Medical application,silicone rubber cables used are usually (SiHF silicone cable ,Silicone Halogen Free ).

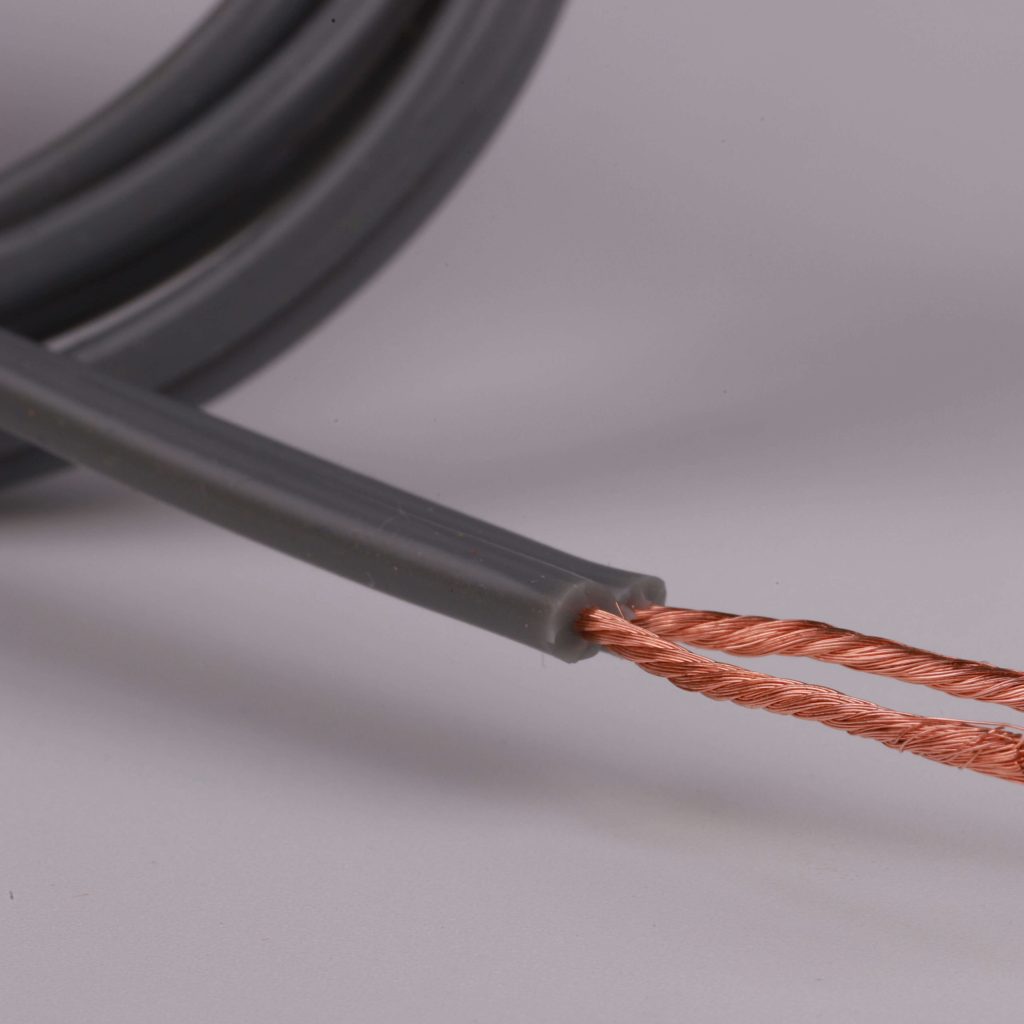

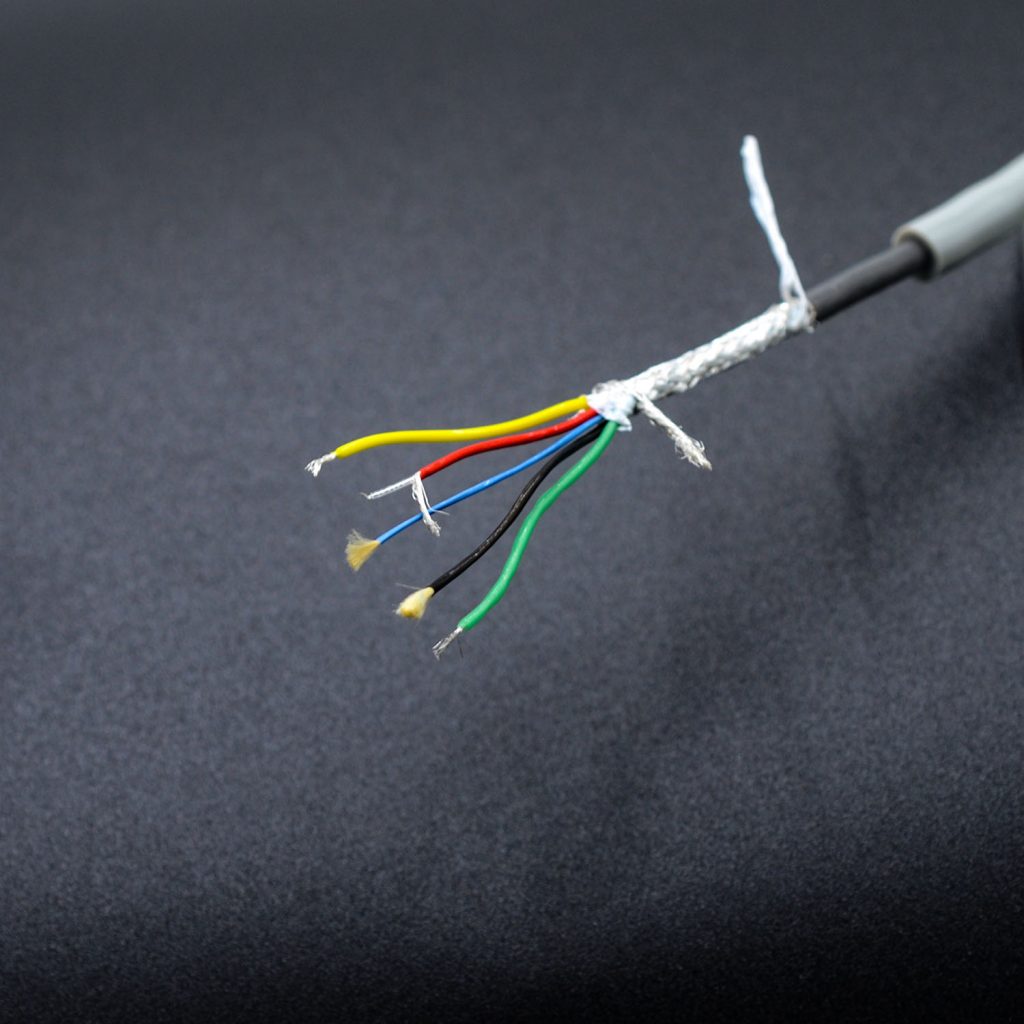

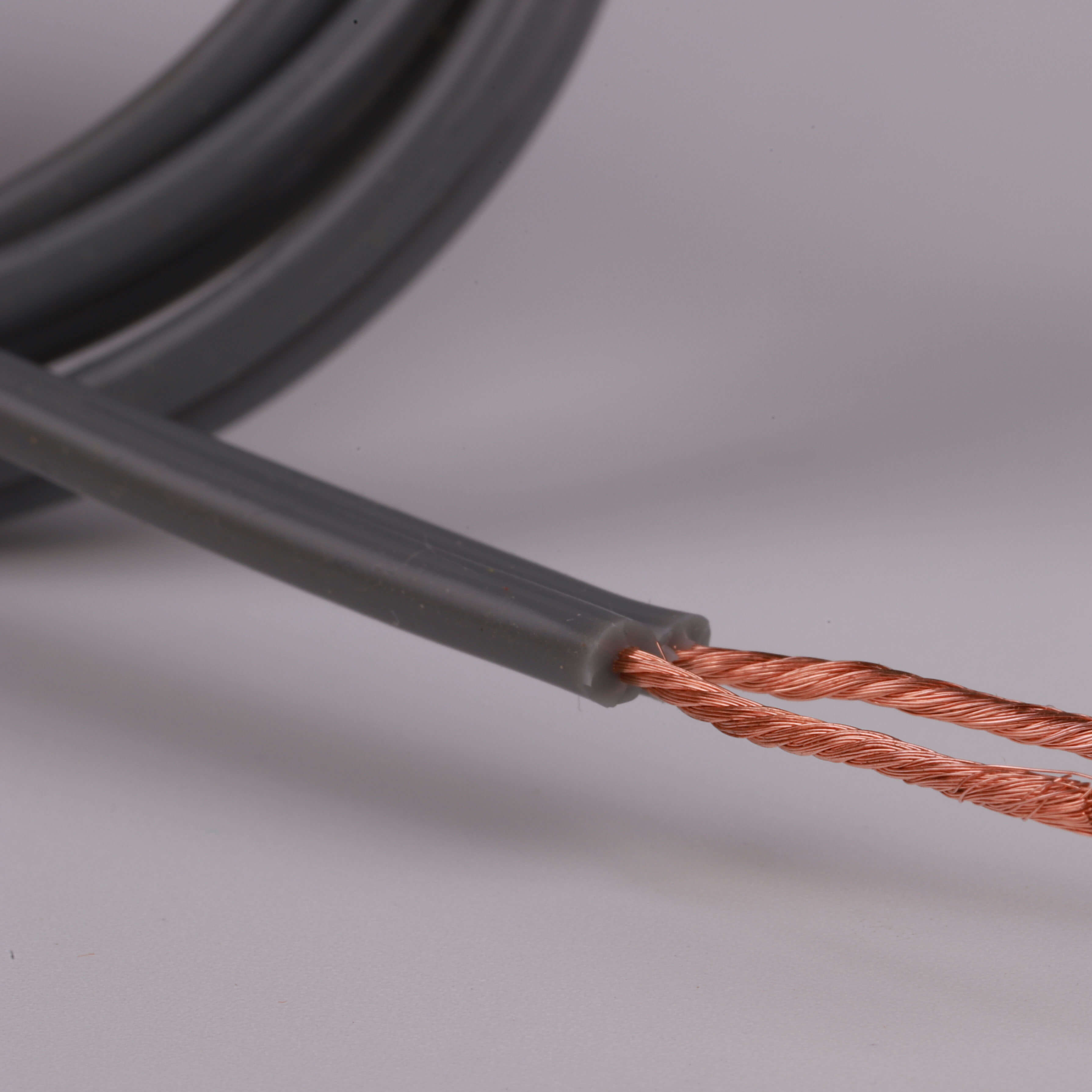

Have a Check if partial of our existing silicone rubber cable can help your business.More options,please contact us directly

What is Silicone rubber cable ?

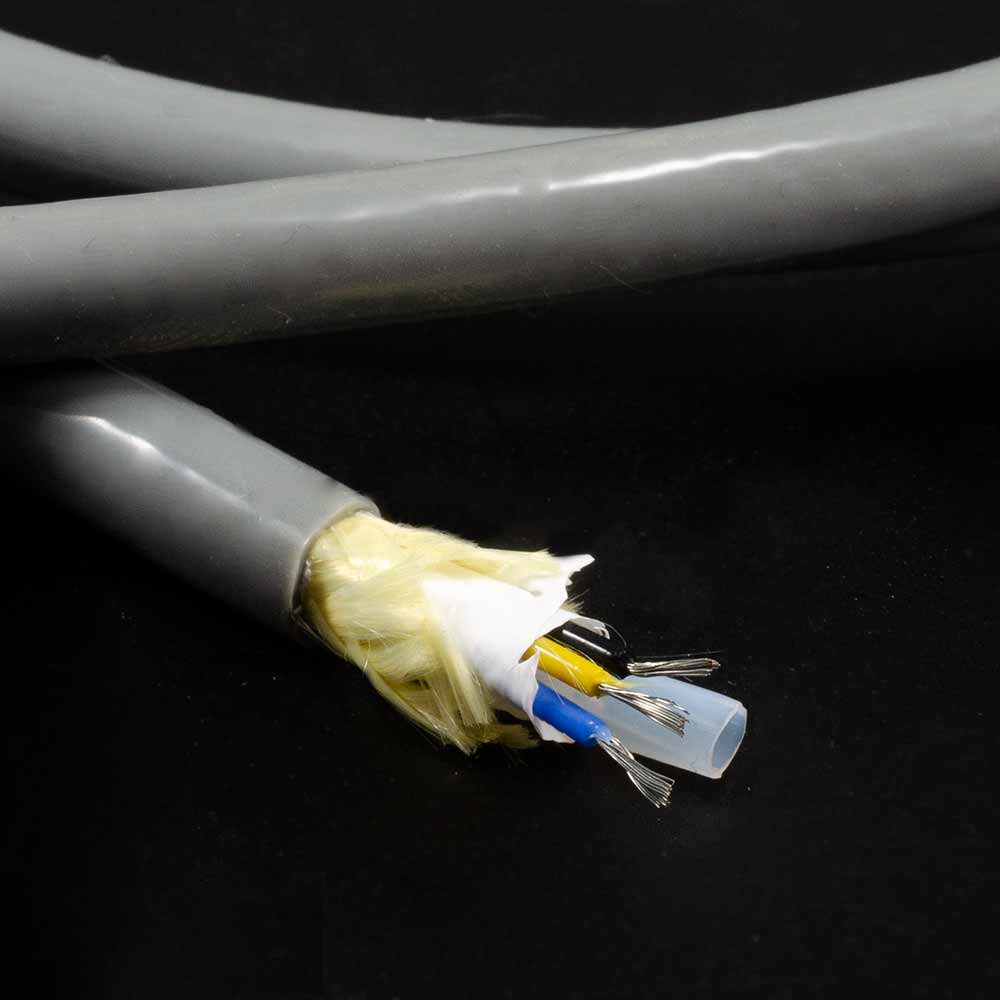

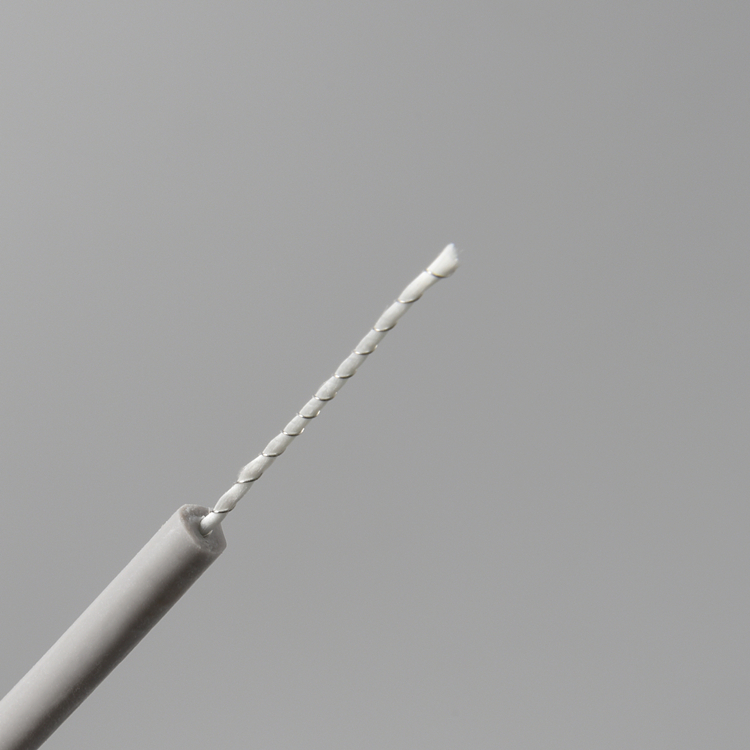

Generally speaking, silicone cable means cable with Silicone rubber insulated,this type of silicone cable is more accurately to call it “silicone wire” or “silicone insulated wire” if we study the definition difference tween wire and cable, in which “wire” is defined as “A wire consists of a single strand or a group of strands of an electrically conductive material (conductor). This material is normally composed of aluminum or copper. Wires can come bare, or covered in a protective or color-coded sheath.” It fully use the excellent properties of silicone rubber. In some way, when we are talking about the advantages of silicon rubber cable, we are talking about the advantage of silicone rubber.

So in some situations, we combine the silicone rubber advantages with others to develop a new customized Silicone rubber cable, in which silicone rubber worked as Jacket, not the insulation. The commonest cable with this combination is :Silicone Jakcet+ insulator Teflon(PTFE、FEP、PFA、ETFE) ,this is another type of Silicone rubber cable.

What is the Key properties and advantages of Silicone cable?

Resistant to extreme temperature

Resistant to high temperature

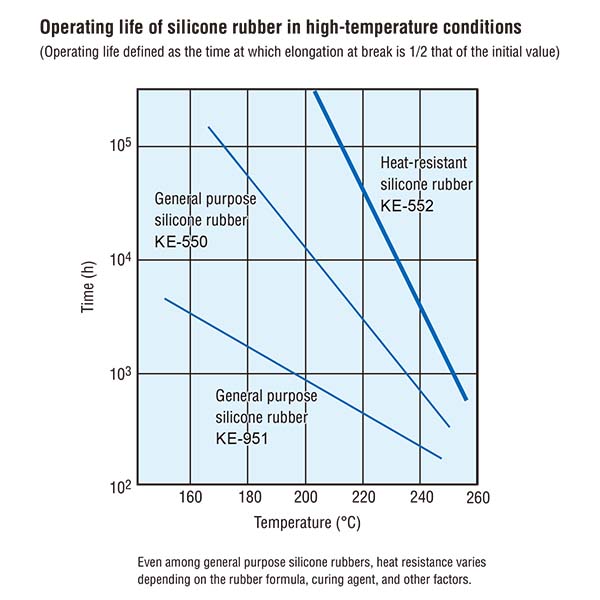

Extruded with a suitable compound, silicone cable can work at an operating temperature up to 300 °C for while (Even 350 with suitable conductors like nickel). And maintain its good mechanical performance within 250 °C for long time using.

Resistant to Low temperature

Silicone cable’s working low temperature range is -60°C.

And remains good electrical and mechanical performance, softness and flexibility if the temperature is no lower than -40 °C. (Silicone’s indurating temperature of around -115°C). So it does not mean if temperature lower than -40, it does not work. Many factors influence its operation, such as, exposing time, atmosphere situation (like oxygen concentration, ozone), and mechanical stress, tension and so on.

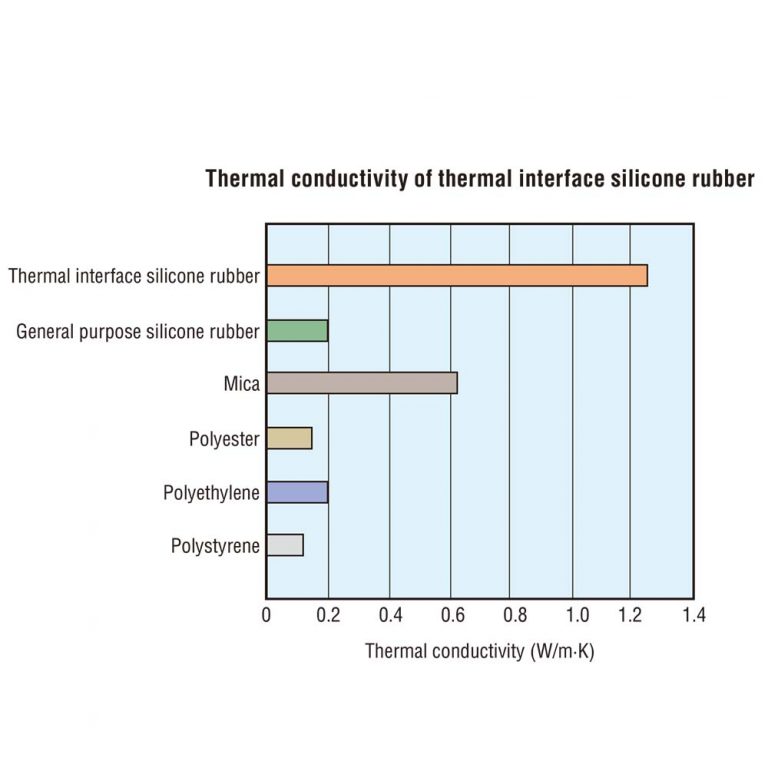

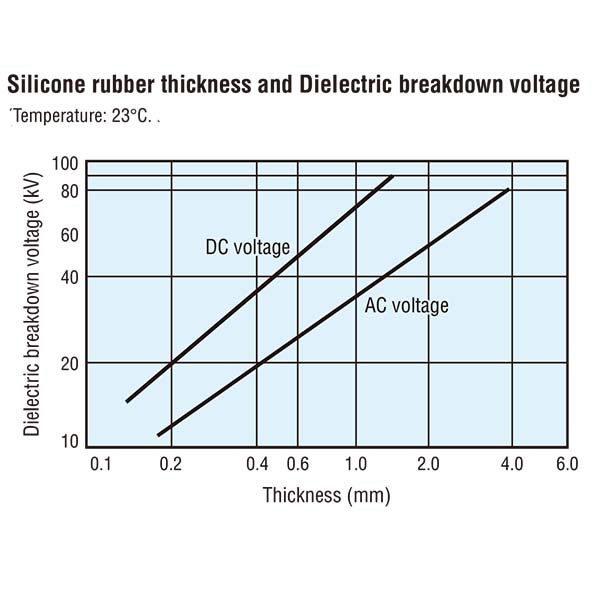

Good dielectric properties /Insulation strength

Silicone rubber has high insulation resistance of 1T·m-100T·m, and its insulating properties are stable over a wide range of temperatures and across a wide frequency spectrum. There is almost no decline in performance even when immersed in water, making silicone rubber an ideal insulating material. It has particularly good resistance to corona discharge and arcing at high voltages. Silicone rubber is thus used extensively as an insulator in high voltage cable.

Silicone rubber insulated wires has perfect dielectric properties, combined with flexibility, when making flexible High Voltage cables, such as 4 awg silicone wire,14awg silicone wire,20 gauge or 22 gauge silicone wire, silicone rubber will be our first optional insulation material, even Teflon also has perfect insulation strength.

Resistant to chemical substances

| Oil and chemical resistance of common methyl vinyl silicone rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| Type of oil/chemical | Immersion conditions | Change in properties | ||||||

| °C x h | Hardness points | Weight % | Volume % | Tensile strength % | Elongation % | |||

| Oil | ASTM #1 oil | 150 x 168 | -10 | +10 | -10 | -10 | ||

| ASTM #3 oil | 150 x 168 | -25 | +40 | -20 | -20 | |||

| GM Hydramatic Fluid | 94 x 70 | -35 | +35 | -40 | -5 | |||

| Ford Brake Fluid | 150 x 72 | -20 | +15 | -60 | -40 | |||

| Diesel Fuel | 50 x 168 | -30 | +105 | — | — | |||

| Gasoline | 23 x 168 | -20 | +165 | — | — | |||

| Skydrol 500A Fluid | 70 x 168 | -5 | +10 | -10 | +5 | |||

| Motor oil (SAE #30) | 175 x 168 | -8 | -8 | -70 | -65 | |||

| Chemical | Acid | Conc. Nitric acid | 25 x 168 | +10 | +10 | -80 | 30 | |

| 7% Nitric acid | 25 x 168 | < 1 | < 1 | -50 | -30 | |||

| Conc. Sulfuric acid | 25 x 168 | Dissolves | Dissolves | Dissolves | Dissolves | |||

| 10% Sulfuric acid | 25 x 168 | < 1 | < 1 | 0 | 0 | |||

| Acetic acid | 25 x 168 | +3 | +4 | -20 | +10 | |||

| 5% Acetic acid | 25 x 168 | +2 | +2 | -20 | +10 | |||

| Conc. Hydrochloric acid | 25 x 168 | +3 | +4 | -40 | -20 | |||

| 10% Hydrochloric acid | 25 x 168 | +2 | +2 | -50 | -50 | |||

| Alkali | 10% Sodium hydroxide solution | 25 x 168 | -2 | -1 | -10 | 0 | ||

| 2% Sodium hydroxide solution | 25 x 168 | < 1 | < 1 | 0 | 0 | |||

| Conc. Ammonia water | 25 x 168 | +2 | +1 | -30 | +10 | |||

| 10% Ammonia water | 25 x 168 | +2 | +2 | -20 | 0 | |||

| Other | Water | 25 x 168 | <1 | <1 | 0 | 0 | ||

| 100 x 70 | <1 | <1 | -10 | -10 | ||||

| 70 x 168 | +1 | < 1 | -10 | +10 | ||||

| 3% Hydrogen peroxide solution | 25 x 168 | < 1 | < 1 | 0 | +20 | |||

Resistant to Physical Destruction

Resistant to flame and fire

Silicone jacket wire is a typical Sihf cable (Silicone Insulated Halogen free), lszh cable (low smoke zero halogen cable) and UL cable such as UL3512 UL3535 UL4535.

High temperature Silicone cables are flame retardant .In case of a fire. The Silicone Jacket or & and insulation crystallize and generate a silica film to cover the conductors, thus remains its insulation properties and to prevent a disaster of circuit or electricity network.

With special retardant compounds, the LOI value (Limiting Oxygen Index) can be increased up to 120-125%.

Physical stretch (Elongation)

Silicone has high elongation (stretch) which helps flexibility and strength. There is little change in silicone rubber cable even at 250°C.it closely related with the silicone rubber insulation.

Elongation generally refers to “ultimate elongation” or percent increase in original length of a specimen when it breaks.

Typical elongation ranges are listed here. (Note: silicone rubber’s elongation does not equal to silicone cables, elongation)

HCR – High Consistency Silicone Rubber typical elongation range from 90 to 1120%.

FSR – Fluorosilicone Rubber – typical elongation range from 159 to 699%.

LSR – Liquid Silicone Rubber – typical elongation range from 220 to 900%.

*Different processing methods and oven cures change the values considerably.

The thermal characteristics section shows that the elongation of silicone rubber varies linearly with temperature, and holds up longer than most other elastomers.

Waterproof and pressure resistant

Silicone cable has good Waterproof and pressure resistance, combined with its resistant to oil and high temperature, it is an ideal choice for automotive wires user and similar application users

Physical processing

Silicone wires has good resistance to corona, ozone, weathering , UV, aging, radiation.it has good physiological inertness and air permeability .This make it easy to go through many type of physical processing.

Biological Properties

Resistant to Fungus

Silicone itself is not anti-fungicidal, it is neither a food for fungus, so even when there is suitable damp and temperature, fungus or mold will affect the silicone jacket of the cable. And we can formulate the silicone rubber to improve the silicon wires, fungus resistance properties.

Super Biocompatibility

Benefit by the super biocompatibility of silicone rubbers, silicone cable has good compatibility with human tissue and body fluids and an extremely low tissue response when implanted, not to mention a skin contact.

Odorless, tasteless and biological stability, silicones is not a nutrition for bacteria growth and will not stain or pollute others around.

What are disadvantage of silicone rubber cable and caution when using

- Silicone cables can be seriously damaged by ethers, strong alkalis, liquid fuel, esters, chlorinated hydrocarbons and ketones.

- SiHF silicone cable jacket inflate when touched with naphthenic oils.

- Silicone cable will be out of service when contacting aromatic base oils at high temperatures (higher than 130-140 °C)

- Silicone able has poor abrasion resistance. The silicone wire jacket / sheath is cold extruded after vulcanizing the silicone rubber. The density is not as good as Heat extruded jacket of other materials. It is easy to scrape by sharp objects. So it is better to be applied in static situations and keep away from sharp objects or movement on rough surface.

- Surface is it easy to sticky to dust.

Silicone cable’s high Price is a fatal disadvantage

The main reason for the high price of silicone cable is the high cost of silicone rubber and silicone cable manufacturing progress .The cost of silicone rubber is 2-3 times of common plastic materials, and for medical level silicone rubber, its cost is even higher. For Common plastic jacket cable, it only take one step to finish the Insulation/ Jacket extruding. For Silicone cable, it need two steps:

Step1:Silicone rubber vulcanization

Step2:Cold Extrude

The more steps it take, the harder it is to control and more lose will cause.

Silicone cable Applications

Applications in medical

No matter it is Class 1, Class 2, or Class 3 medical devices or accessories, Silicone cable application can be found everywhere. Sterilization and Biocompatibility are prior concerns .As mentioned in silicone cable properties, it is clear that SiHF silicone cable is absolutely an ideal choice for medical applications. Such as monitoring system sensor, robotic arms, imaging system, Spo2 sensor, ECG/EKG,High-End ESU(Electrosurgical Unit)

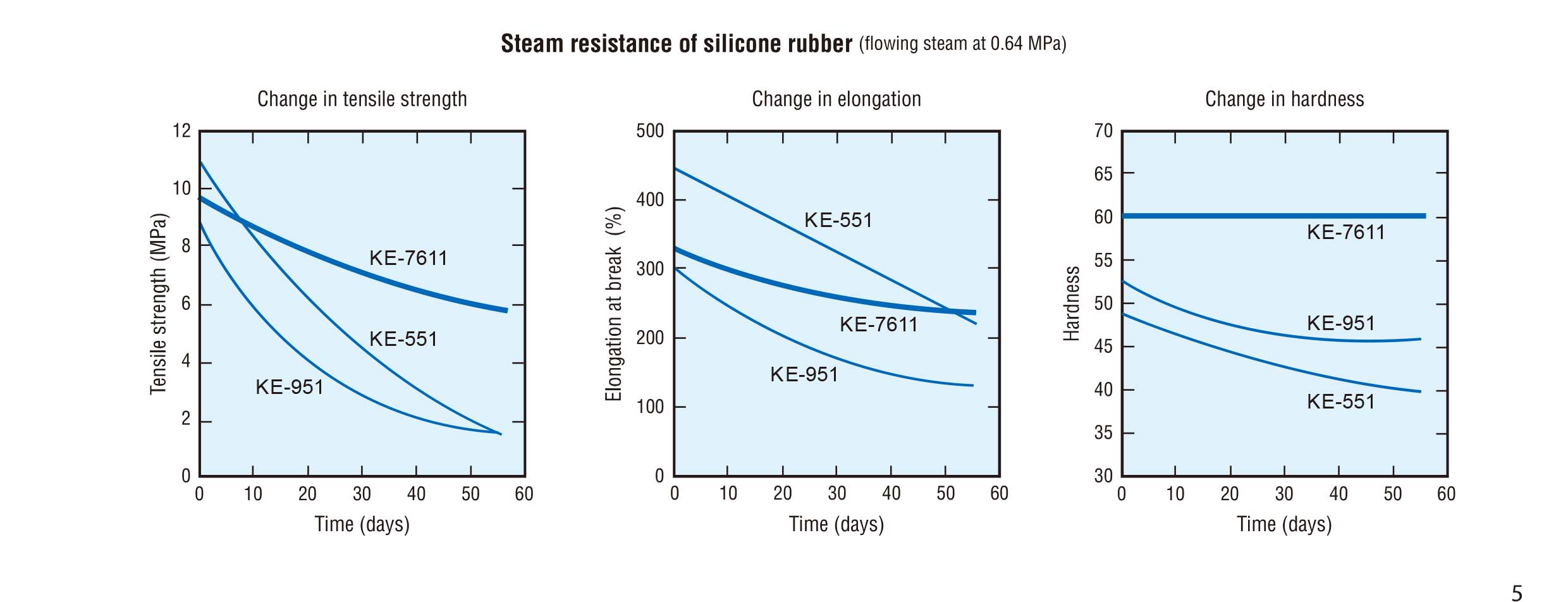

Most Medical cable use autoclave sterilization,to the cable need to be autoclave resistant.SiHF silicone cable has good autoclave resitant

Applications in Aerospace

Aerospace applications such as spacecraft – Satellites, which has high requirement for “Radiation Resistant, Flexibility, Low Outgassing”, silicone cable can deal with these situation.

Applications in Undersea and Naval

Naval and undersea (Tow, Tether, Sonar Video, ROV, Lighting, Umbilical, Geophysical) activities usually need the cable to be Flame Retardant, Low Smoke, Low Halogen, there are many considerations such as Buoyancy, Atmospheric Pressure, Ruggedness

Applications in Industry

Used in electrical connection between mobile electrical equipment in high temperature environments such as power generation, metallurgy, chemical industry, etc.

need a customize a silicone rubber cable?

Leave us your Specification or Engineer structure!!!

- All

- Blog

- Medical cables

- Uncategorized

- raw cable