Non Magnetic RF Cable And Non Ferrous RF Cable In MRI Application

Non magnetic RF cable and Non Ferrous RF Cable are crucial components in Magnetic Resonance Imaging (MRI) applications, serving the purpose of transmitting RF pulse signals and receiving the weak signals produced by the proton rearrangement within a magnetic field. As MRI technology advances, greater scan resolution and stronger magnetic fields are required, which in turn necessitates more densely packed RF cables for optimal imaging quality. Meeting these demands is a challenge for the design, manufacture, and maintenance of MRI equipment.

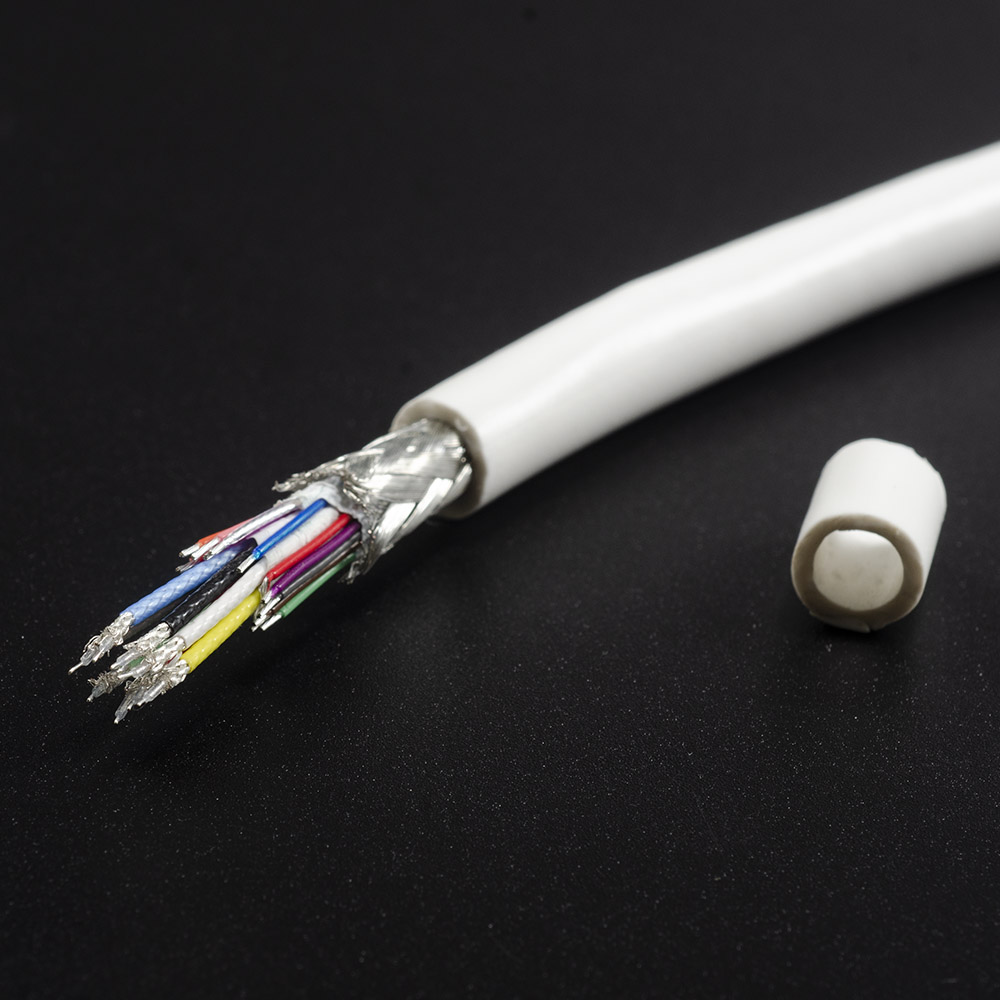

8 wire Non Magnetic RF cable +18 Non Magnetic signal wire

RF Coaxial Cable With 8 Coaxial 32AWG And 18x 28AWG Wire. This 26 wire MRI compatible RF Coaxial Cable is intended for mri coil manufacturers and repair service provider

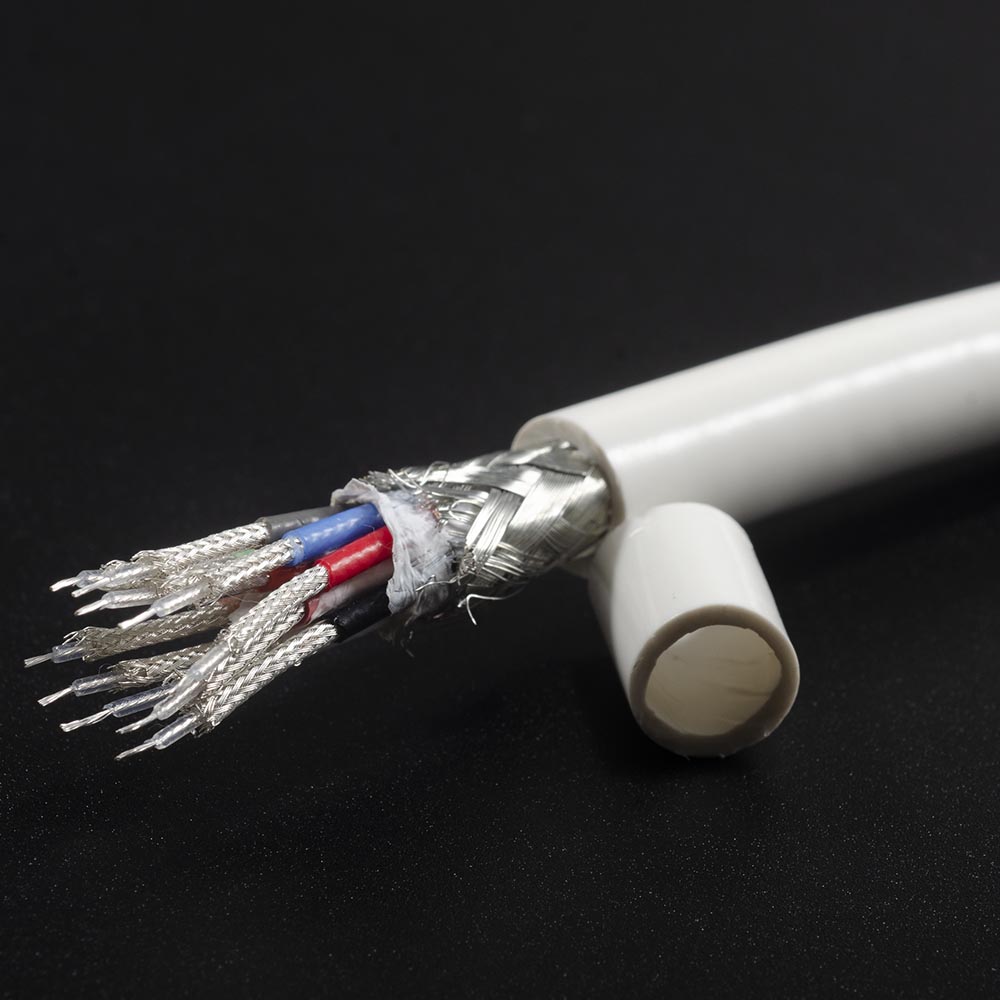

10 Non Magnetic Wire RF cable 50ohm

RF Coax Cable includes 10 Coax RG178, Silver plated Copper wire Conductor,Non Magnetic Non ferrous contents included

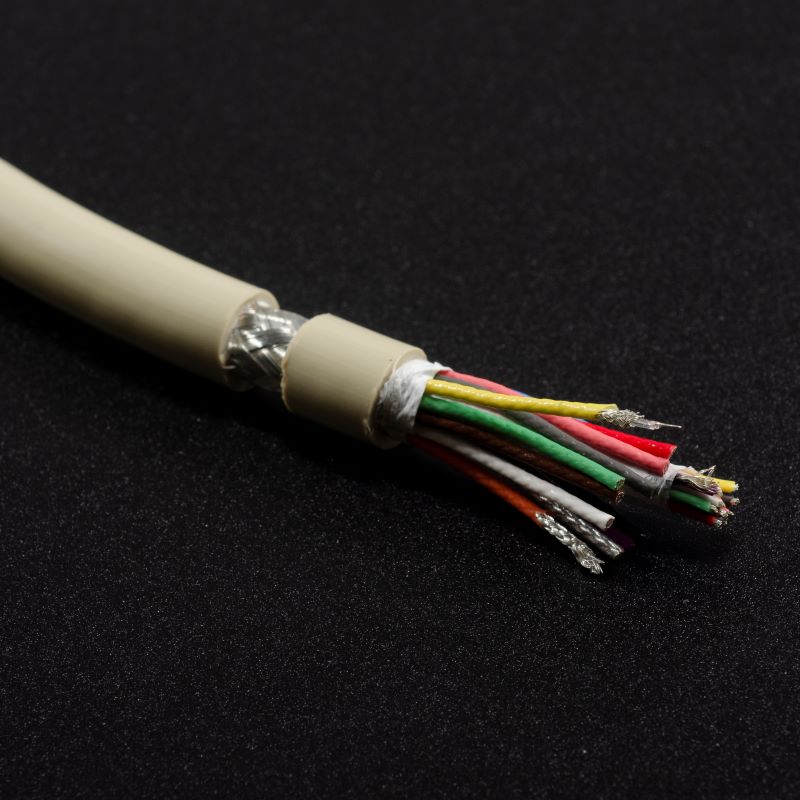

12 Non Magnetic wire RF cable +12 Non Magnetic signal wire

The 24 Wire MRI Cable With 12 Coax 32AWG And 12x 26AWG Signal Wire is widely used in MRI Machine repair

Demand for Non-Ferrous RF Cables in MRI While Magnetic Resonance Imaging (MRI) has found a wide range of applications across neuroscience and medical fields, its unique benefits have driven its increasing use in healthcare and the development of compatible medical devices. To meet these needs, advanced MRI technology must be developed, with an emphasis on higher magnetic field strength and resolution.

Current research on MRI advancements focuses on increasing magnetic field strength, with the goal of upgrading from current 1.5 to 3 Tesla MRI machines to 7 or even higher Tesla. These advancements will require non-ferrous RF cables with high quality for transmitting RF pulse signals and receiving weak signals from proton rearrangement, which will be more numerous and densely packed than before. Meeting this demand presents new challenges in designing, manufacturing, and maintaining MRI equipment.

RF Cable Challenges for MRI/MRA Current MRI machines use many RF cables, contact points, and cables to transmit and receive RF signals for patient imaging. The presence of any ferromagnetic material within these components may change the magnetic response from the patient, thus lowering the accuracy of MRI. Consequently, MRI machines usually use non-magnetic RF cables and contact points that have been tested to ensure they do not produce a magnetic response.

Although using non-magnetic RF cables and contact points can achieve higher-resolution MRIs, further advancements in MRI technology will require more from these components than just non-magnetic properties. Higher magnetic field strengths are required to achieve higher resolution and signal-to-noise ratios, even for high-Tesla MRI machines. Thus, RF receivers and transmission paths must introduce minimal loss and distortion. Additionally, new types of MRI probes that use magnetic field probes instead of traditional surface coils are being studied and developed, which require more RF cables and signal processing circuits.

More densely packed RF cables mean that apart from the common non-magnetic RF connectors, more board-to-board RF cables and end-to-end RF cables may also be required. However, compared to standard RF cables, there are relatively few non-magnetic RF solutions available from RF cable vendors, limiting choices for MRI manufacturers in reducing the size and complexity of their designs. Difficulty in obtaining high-quality and reliable non-magnetic RF cables may be encountered by MRI manufacturers.

Non-Ferrous RF Cables in Medical Applications RF cable considerations include size, frequency, power handling, and insertion loss. Smaller RF cables usually transmit higher-frequency signals but are limited in terms of maximum power handling and have increased insertion loss. Special design techniques and materials can be used to mitigate insertion losses when using smaller RF cables, allowing for smaller RF connections. While not every vendor has all types of RF cables, non-magnetic RF cables used for MRI include N-type, SMA, BNC, SMB, SMC, MCX, MMCX, SMP, SMPM, and 2.92 mm, with cable type depending on factors such as frequency, signal power, geometric shape of connection points, insertion loss considerations, and installation dynamics.

MRI technology is increasingly used in medical applications, including cardiac imaging and magnetic resonance angiography (MRA). While traditional implants with ferromagnetic materials, such as stents or pacemakers, may prevent patients from using MRI machines, an increasing number of implantable medical devices intentionally use non-ferrous components to allow for high-resolution MRI scans rather than just conventional CT or SPECT scans. Another trend is the use of wireless connections rather than wired connections for accessing, controlling, and monitoring the functionality of implanted medical electronic devices. For implantable medical devices that use wireless technology, non-magnetic RF cables are required to be MRI-compatible. As these fields and applications grow, the demand for non-magnetic RF cables for implantable medical electronics may increase.

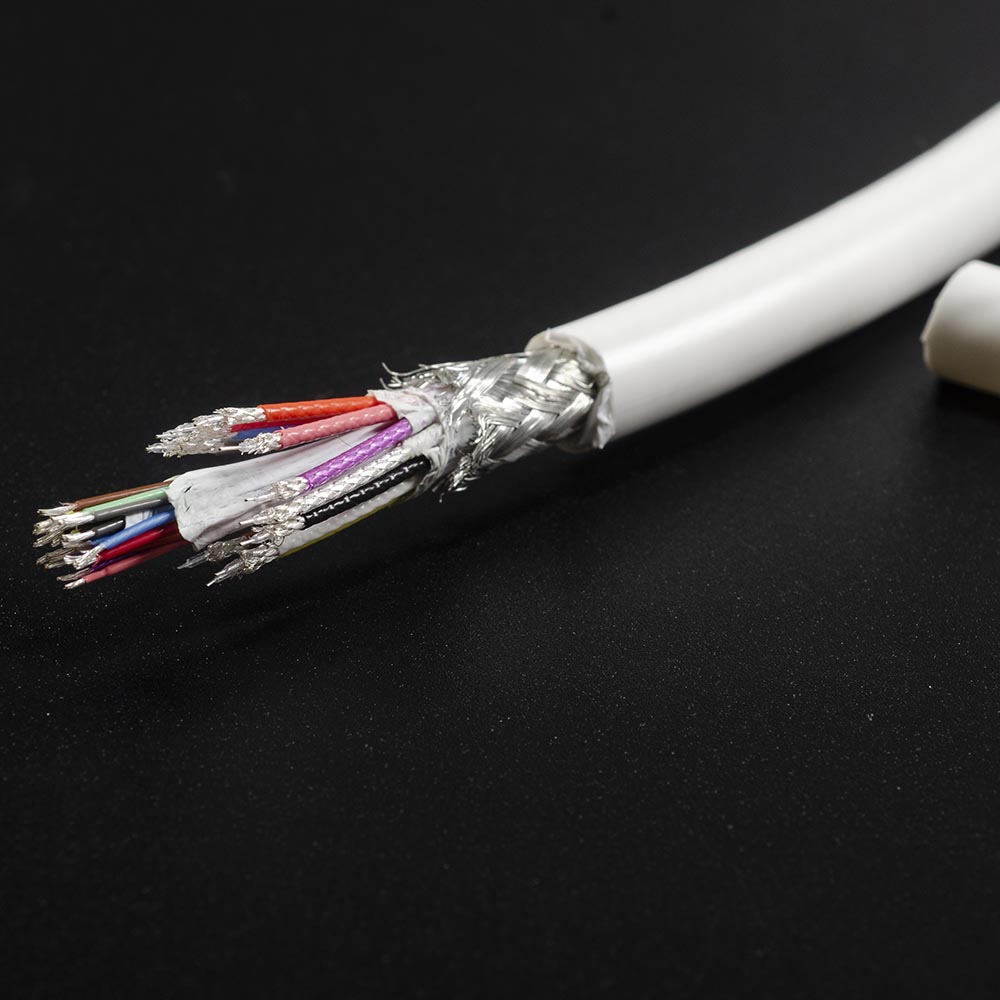

32 core Custom Non Ferrous Cables With 12 Coaxial 50Ω

This 32 Wire cable is a Custom RF Cables With 12 Coaxial Cable 50Ω,32AWG and 20X 28AWG Wire ,it is widely used in MRI RF Coils .

Multi Coax Cable With 16x 50ohm Coaxial RF Cable RG 178

32 Wire Multi Coax Cable With 16x 50ohm Coaxial Cable RG 178 And 16x 26AWG Wire

Non magnetic RF cables, also known as non ferrous RF cables, play a crucial role in Magnetic Resonance Imaging (MRI) applications. These cables are specifically designed to meet the demanding requirements of MRI technology, ensuring accurate and high-quality imaging results. As an experienced manufacturer of these cables, our company specializes in producing top-notch non magnetic RF cables that excel in MRI applications.

The importance of Non magnetic RF cables in MRI cannot be overstated. These cables serve several key functions:

Transmitting RF Pulse Signals: Non magnetic RF cables are responsible for transmitting RF pulse signals to specific regions of the patient’s body, enabling the excitation and manipulation of proton alignment within the magnetic field. Through the RF transmission path, such as coils, these signals are delivered to the target area to facilitate the desired imaging process.

Receiving Weak Signals: Non magnetic RF cables are also utilized to receive the weak signals emitted by the reorientation of protons. These faint signals, known as Free Induction Decay (FID), need to be transmitted back through the RF cables to the receiver for processing and amplification, resulting in the final image generation.

Enhancing Signal-to-Noise Ratio (SNR): The quality and design of non magnetic RF cables directly influence signal transmission efficiency and SNR. High-quality cables minimize signal loss and interference, leading to improved image quality and clarity. Optimized cable designs reduce electromagnetic interference, RF energy coupling, and other unnecessary noise, enhancing imaging sensitivity and accuracy.

Supporting High Field Strengths: With the continuous advancement in MRI technology, higher magnetic field strengths have become prevalent, ranging from 1.5 Tesla to 3 Tesla, 7 Tesla, and even higher. This upgrade requires RF cables capable of withstanding higher current and power, as well as materials that can function reliably under stronger magnetic fields.

Our company, as an experienced manufacturer, understands the critical importance of non magnetic RF cables in MRI applications. We specialize in producing premium non magnetic RF cables that meet the stringent compatibility requirements of MRI equipment while ensuring zero magnetic field response. Our cables are designed to withstand high power, minimize signal loss, and provide exceptional image quality.