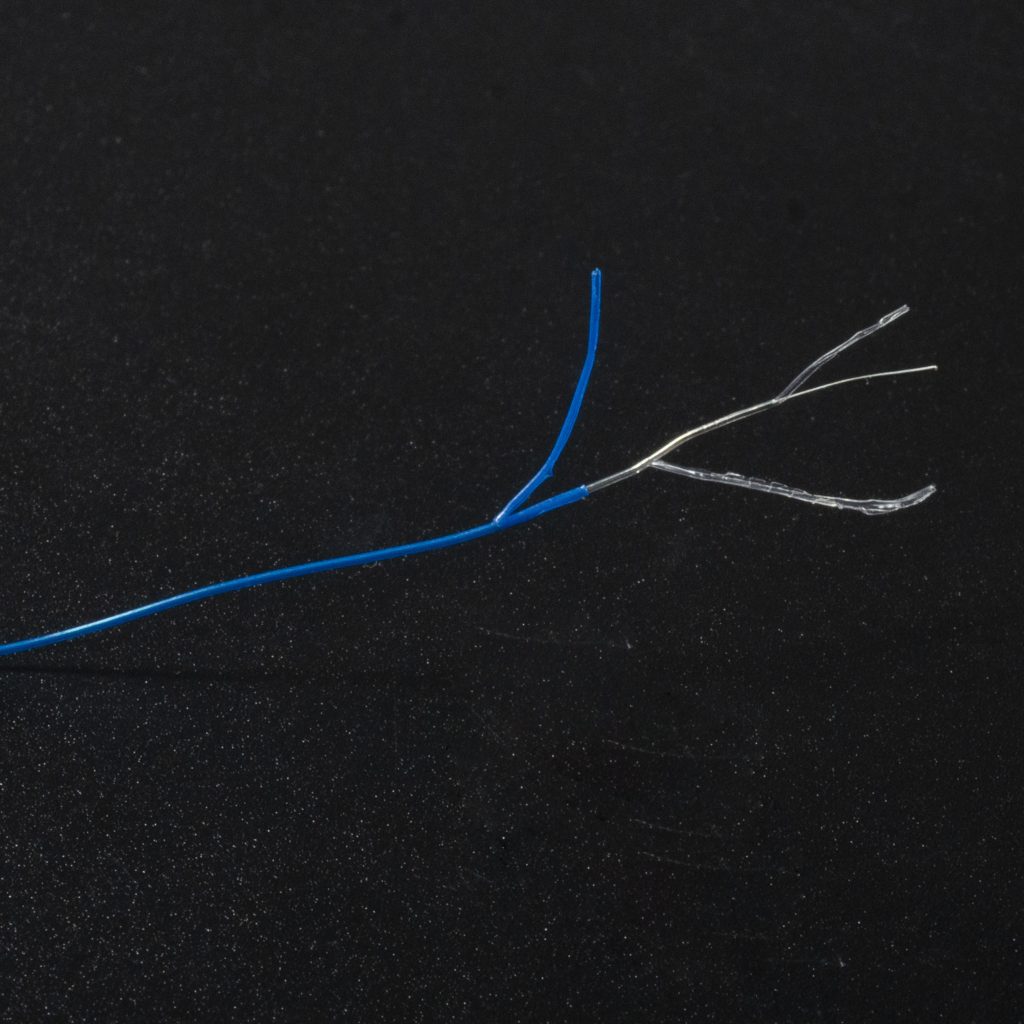

Triple Insulated Litz Wire-ETFE FEP and FPA insulation optional

Triple insulated Litz wire is increasingly recognized for its ability to enhance performance.Especially micro litz wire,such as 30AWG-40AWG,big size (such as 13AWG avaible too).tripple insulation enhance its electronic performance and mechanical performance .

Not only mirco litz wire need to be triple insulated. Big section area litz wire can also use 3 layers insulation to enhace their performance

Understanding Triple Insulated Litz Wire

Triple insulated Litz wire consists of one single conductor or multiple insulated conductors twisted together, surrounded by three layers of insulation. This construction significantly reduces energy losses and minimizes signal distortion, making it ideal for applications such as transformers, motors, and high-frequency communication devices.

Triple insulated Litz wire presents a powerful solution for high-frequency applications, balancing the challenges of design and production with significant benefits. As a manufacturer specializing in this technology(only only triple insulated litz wire,double insulated litz wire available too ), we offer customized solutions using ETFE, PFA, and FEP insulation materials, along with free samples to help you make informed decisions. By choosing triple insulated Litz wire, you can enhance the performance and reliability of your electrical systems.

Following are some Single insulated,Double insulated and triple insulated litz wire

Insulation Thickness:

- PFA:0015″ min per layer

- FEP:002″ min per layer

- ETFE:0015″ min per layer

Voltage Rating:

- single layer 600 Vpk

- Double layers 1000 Vpk

- Triple layers 1000 Vpk

Temperature Rating:

- PFA:UL/VDE Class H 180℃

- FEP:UL/VDE Class H 180℃

- ETFE:UL/VDE Class F 155℃

Dielectric Strength:

- PFA:2000V/mil nominal

- FEP:2000V/mil nominal

- PFA:1800V/mil nominal

| Conductor | Single Insulated | Double Insulated | Triple Insulated | ||||||

|---|---|---|---|---|---|---|---|---|---|

| AWG | OD(m m) | DC Resistance | Part Num ber | OD(mm) | Part Number | OD(mm) | Part Number | OD(mm) | |

| Bare | Tinned | ||||||||

| 18 | 1.02 | 6.516 | 6.995 | | | YL18D1.5PXXTC1A | 1.176 | YL 18T 1.5PXXXTC1A | 1.252 |

| 19 | 0.912 | 8.211 | 8.815 | YL19D1.5PXXTC1A | 1.064 | YL 19T1.5PXXXTC1A | 1.140 | ||

| 20 | 0.813 | 10.33 | 11.09 | YL20D1.5PXXTC1A | 0.965 | YL 20T1.5PXXXTC1A | 1.041 | ||

| 21 | 0.724 | 13.03 | 13.99 | YL21D1.5PXXTC1A | 0.876 | YL 21T1.5PXXXTC1A | 0.952 | ||

| 22 | 0.643 | 16.53 | 17.75 | YL22S1.5PXTC1A | 0.719 | YL22D1.5PXXTC1A | 0.795 | YL 22T1.5PXXXTC1A | 0.871 |

| 23 | 0.574 | 20.72 | 22.24 | YL23S1.5PXTC1A | 0.65 | YL23D1.5PXXTC1A | 0.7 26 | YL 23T1.5PXXXTC1A | 0.802 |

| 24 | 0.511 | 26.19 | 28.12 | YL24S1.5PXTC1A | 0.587 | YL24D1.5PXXTC1A | 0.663 | YL 24T1.5PXXXTC1A | 0.739 |

| 25 | 0.455 | 33.03 | 35.46 | YL25S1.5PXTC1A | 0.531 | YL25D1.5PXXTC1A | 0.607 | YL 25T1.5PXXXTC1A | 0.683 |

| 26 | 0.404 | 41.86 | 44.94 | YL 26S1.5PXTC1A | 0.48 | YL26D1.5PXXTC1A | 0.556 | YL 26T 1.5PXXXTC1A | 0.632 |

| 27 | 0.361 | 52.48 | 56.34 | YL27S1.5PXTC1A | 0.437 | YL27D1.5PXXTC1A | 0.513 | YL 27T1.5PXXXTC1A | 0.589 |

| 28 | 0.32 | 66.66 | 71.56 | YL28S1.5PXTC1A | 0.396 | YL28D1.5PXXTC1A | 0.472 | YL 28T1.5PXXXTC1A | 0.548 |

| 29 | 0.287 | 82.88 | 88.97 | YL29S1.5PXTC1A | 0.363 | YL29D1.5PXXTC1A | 0.4 39 | YL 29T1.5PXXXTC1A | 0.515 |

| 30 | 0.254 | 105.8 | 113.6 | YL30S1.5PXTC1A | 0.33 | YL30D1.5PXXTC1A | 0.406 | YL 30T1.5PXXXTC1A | 0.482 |

| 31 | 0.226 | 133.9 | 143.8 | YL31S1.5PXTC1A | 0.302 | YL31D1.5PXXTC1A | 0.378 | YL 31T1.5PXXXTC1A | 0.454 |

| 32 | 0.203 | 166.2 | 178.4 | YL32S1.5PXTC1A | 0.279 | YL32D1.5PXXTC1A | 0.355 | YL 32T1.5PXXXTC1A | 0.431 |

| 33 | 0.18 | 211.7 | 228.2 | YL33S1.5PXTC1A | 0.256 | YL33D1.5PXXTC1A | 0.332 | YL 33T1.5PXXXTC1A | 0.408 |

| 34 | 0.16 | 269.8 | 289.6 | YL34S1.5PXTC1A | 0.236 | YL34D1.5PXXTC1A | 0.312 | YL 34T1.5PXXXTC1A | 0.388 |

| 35 | 0.142 | 342.8 | 368.1 | YL35S1.5PXTC1A | 0.218 | YL35D1.5PXXTC1A | 0.294 | YL 35T1.5PXXXTC1A | 0.37 |

| 36 | 0.127 | 431.9 | 463.7 | YL36S1.5PXTC1A | 0.203 | YL36D1.5PXXTC1A | 0.279 | YL 36T1.5PXXXTC1A | 0.355 |

| 37 | 0.114 | 535.7 | 575.1 | YL37S1.5PXTC1A | 0.19 | YL37D1.5PXXTC1A | 0.266 | YL 37T1.5PXXXTC1A | 0.342 |

| 38 | 0.102 | 681.9 | 732 | YL38S1.5PXTC1A | 0.178 | YL38D1.5PXXTC1A | 0.254 | YL 38T 1.5PXXXTC1A | 0.33 |

| 39 | 0.089 | 897.1 | 963.1 | YL39S1.5PXTC1A | 0.165 | YL39D1.5PXXTC1A | 0.241 | YL 39T1.5PXXXTC1A | 0.317 |

| 40 | 0.079 | 1152 | 1237 | YL40S1.5PXTC1A | 0.155 | YL40D1.5PXXTC1A | 0.231 | YL40T1.5PXXXTC1A | 0.307 |

| Conductor | Single Insulated | Double Insulated | Triple Insulated | ||||||

|---|---|---|---|---|---|---|---|---|---|

| AWG | O D(m m) | DC Resistance | Part Number | OD(mm) | Part Num ber | OD(mm) | Part Number | OD(mm) | |

| Bare | Tinned | ||||||||

| 18 | 1.02 | 6.516 | 6.995 | YL 18S2.0FXTC1A | 1.12 | YL 18D2.0FXXTC1A | 1.22 | YL 18T2.0FXXXTC 1A | 1.32 |

| 19 | 0.912 | 8.211 | 8.815 | YL 19S2.0FXTC1A | 1.012 | YL 19D 2.0FXXTC 1A | 1.112 | YL 19T2.0FXXXTC 1A | 1.212 |

| 20 | 0.813 | 10.33 | 11.09 | YL 20S2.0FXTC 1A | 0.913 | YL 20D2.0FXXTC1A | 1.013 | YL 20T2.0FXXXTC 1A | 1.113 |

| 21 | 0.724 | 13.03 | 13.99 | YL 21S2.0FXTC 1A | 0.824 | YL 21D2.0FXXTC 1A | 0.924 | YL 21T2.0FXXXTC 1A | 1.024 |

| 22 | 0.643 | 16.53 | 17.75 | YL 22S2.0FXTC 1A | 0.743 | YL 22D2.0FXXTC1A | 0.843 | YL 22T2.0FXXXTC 1A | 0.943 |

| 23 | 0.574 | 20.72 | 22.24 | YL 23S2.0FXTC 1A | 0.674 | YL 23D 2.0FXXTC 1A | 0.774 | YL 23T2.0FXXXTC 1A | 0.874 |

| 24 | 0.511 | 26.19 | 28.12 | YL 24S2.0FXTC 1A | 0.611 | YL 24D 2.0FXXTC 1A | 0.711 | YL 24T2.0FXXXTC 1A | 0.811 |

| 25 | 0.455 | 33.03 | 35.46 | YL 25S2.0FXTC1A | 0.555 | YL 25D 2.0FXXTC1A | 0.655 | YL 25T2.0FXXXTC 1A | 0.755 |

| 26 | 0.404 | 41.86 | 44.94 | YL 26S2.0FXTC1A | 0.504 | YL 26D 2.0FXXTC1A | 0.604 | YL 26T2.0FXXXTC 1A | 0.704 |

| 27 | 0.361 | 52.48 | 56.34 | YL 27S2.0FXTC1A | 0.461 | YL 27D 2.0FXXTC1A | 0.561 | YL 27T2.0FXXXTC 1A | 0.661 |

| 28 | 0.32 | 66.66 | 71.56 | YL 28S2.0FXTC 1A | 0.42 | YL 28D2.0FXXTC1A | 0.52 | YL 28T2.0FXXXTC 1A | 0.62 |

| 29 | 0.287 | 82.88 | 88.97 | YL 29S2.0FXTC 1A | 0.387 | YL 29D 2.0FXXTC1A | 0.487 | YL 29T2.0FXXXTC1A | 0.587 |

| 30 | 0.254 | 105.8 | 113.6 | YL 30S2.0FXTC1A | 0.354 | YL 30D 2.0FXXTC 1A | 0.454 | YL 30T2.0FXXXTC 1A | 0.554 |

| 31 | 0.226 | 133.9 | 143.8 | YL 31S2.0FXTC 1A | 0.326 | YL 31D 2.0FXXTC 1A | 0.426 | YL 31T2.0FXXXTC 1A | 0.526 |

| 32 | 0.203 | 166.2 | 178.4 | YL 32S2.0FXTC 1A | 0.303 | YL 32D 2.0FXXTC 1A | 0.403 | YL 32T2.0FXXXTC 1A | 0.503 |

| 33 | 0.18 | 211.7 | 228.2 | YL 33S2.0FXTC 1A | 0.28 | YL 33D 2.0FXXTC 1A | 0.38 | YL 33T2.0FXXXTC 1A | 0.48 |

| 34 | 0.16 | 269.8 | 289.6 | YL 34S2.0FXTC1A | 0.26 | YL 34D 2.0FXXTC 1A | 0.36 | YL 34T2.0FXXXTC 1A | 0.46 |

| 35 | 0.142 | 342.8 | 368.1 | YL 35S2.0FXTC1A | 0.242 | YL 35D 2.0FXXTC 1A | 0.342 | YL 35T2.0FXXXTC1A | 0.442 |

| 36 | 0.127 | 431.9 | 463.7 | YL 36S2.0FXTC 1A | 0.227 | YL 36D 2.0FXXTC 1A | 0.327 | YL 36T2.0FXXXTC1A | 0.427 |

| 37 | 0.114 | 535.7 | 575.1 | YL 37S2.0FXTC 1A | 0.214 | YL 37D2.0FXXTC1A | 0.314 | YL 37T2.0FXXXTC 1A | 0.414 |

| 38 | 0.102 | 681.9 | 732 | YL 38S2.0FXTC 1A | 0.202 | YL 38D 2.0FXXTC 1A | 0.302 | YL 38T2.0FXXXTC 1A | 0.402 |

| 39 | 0.089 | 897.1 | 963.1 | YL 39S2.0FXTC 1A | 0.189 | YL 39D 2.0FXXTC 1A | 0.289 | YL 39T2.0FXXXTC 1A | 0.389 |

| 40 | 0.079 | 1152 | 1237 | YL 40S2.0FXTC1A | 0.179 | YL 40D2.0FXXTC1A | 0.279 | YL 40T2.0FXXXTC1A | 0.379 |

| Conductor | Single Insulated | Double Insulated | Triple Insulated | ||||||

|---|---|---|---|---|---|---|---|---|---|

| AWG | OD(mm) | DC Resistance | Part Num ber | OD(mm) | Part Number | OD(mm) | Part Number | OD(mm) | |

| Bare | Tinned | ||||||||

| 18 | 1.02 | 6.516 | 6.995 | YL18S1.5EXTC1A | 1.096 | YL18D1.5EXXTC1A | 1.172 | YL18T1.5EXXXTC1A | 1.248 |

| 19 | 0.912 | 8.211 | 8.815 | YL19S1.5EXTC1A | 0.988 | YL19D1.5EXXTC1A | 1.064 | YL19T1.5EXXXTC1A | 1.14 |

| 20 | 0.813 | 10.33 | 11.09 | YL20S1.5EXTC1A | 0.889 | YL20D1.5EXXTC1A | 0.965 | YL20T1.5EXXXTC1A | 1.041 |

| 21 | 0.724 | 13.03 | 13.99 | YL21S1.5EXTC1A | 0.8 | YL21D1.5EXXTC1A | 0.876 | YL21T1.5EXXXTC1A | 0.952 |

| 22 | 0.643 | 16.53 | 17.75 | YL22S1.5EXTC1A | 0.719 | YL22D1.5EXXTC1A | 0.795 | YL22T1.5EXXXTC1A | 0.871 |

| 23 | 0.574 | 20.72 | 22.24 | YL23S1.5EXTC1A | 0.65 | YL23D1.5EXXTC1A | 0.726 | YL23T1.5EXXXTC1A | 0.802 |

| 24 | 0.511 | 26.19 | 28.12 | YL24S1.5EXTC1A | 0.587 | YL24D1.5EXXTC1A | 0.663 | YL24T1.5EXXXTC1A | 0.739 |

| 25 | 0.455 | 33.03 | 35.46 | YL25S1.5EXTC1A | 0.531 | YL25D1.5EXXTC1A | 0.607 | YL25T1.5EXXXTC1A | 0.683 |

| 26 | 0.404 | 41.86 | 44.94 | YL26S1.5EXTC1A | 0.48 | YL26D1.5EXXTC1A | 0.556 | YL26T1.5EXXXTC1A | 0.632 |

| 27 | 0.361 | 52.48 | 56.34 | YL27S1.5EXTC1A | 0.437 | YL27D1.5EXXTC1A | 0.513 | YL27T1.5EXXXTC1A | 0.589 |

| 28 | 0.32 | 66.66 | 71.56 | YL28S1.5EXTC1A | 0.396 | YL28D1.5EXXTC1A | 0.472 | YL28T1.5EXXXTC1A | 0.548 |

| 29 | 0.287 | 82.88 | 88.97 | YL29S1.5EXTC1A | 0.363 | YL29D1.5EXXTC1A | 0.439 | YL29T1.5EXXXTC1A | 0.515 |

| 30 | 0.254 | 105.8 | 113.6 | YL30S1.5EXTC1A | 0.33 | YL30D1.5EXXTC1A | 0.406 | YL30T1.5EXXXTC1A | 0.482 |

| 31 | 0.226 | 133.9 | 143.8 | YL31S1.5EXTC1A | 0.302 | YL31D1.5EXXTC1A | 0.378 | YL31T1.5EXXXTC1A | 0.454 |

| 32 | 0.203 | 166.2 | 178.4 | YL32S1.5EXTC1A | 0.279 | YL32D1.5EXXTC1A | 0.355 | YL32T1.5EXXXTC1A | 0.431 |

| 33 | 0.18 | 211.7 | 228.2 | YL33S1.5EXTC1A | 0.256 | YL33D1.5EXXTC1A | 0.332 | YL33T1.5EXXXTC1A | 0.408 |

| 34 | 0.16 | 269.8 | 289.6 | YL34S1.5EXTC1A | 0.236 | YL34D1.5EXXTC1A | 0.312 | YL34T1.5EXXXTC1A | 0.388 |

| 35 | 0.142 | 342.8 | 368.1 | YL35S1.5EXTC1A | 0.218 | YL35D1.5EXXTC1A | 0.294 | YL35T1.5EXXXTC1A | 0.37 |

| 36 | 0.127 | 431.9 | 463.7 | YL36S1.5EXTC1A | 0.203 | YL36D1.5EXXTC1A | 0.279 | YL36T1.5EXXXTC1A | 0.355 |

| 37 | 0.114 | 535.7 | 575.1 | YL37S1.5EXTC1A | 0.19 | YL37D1.5EXXTC1A | 0.266 | YL37T1.5EXXXTC1A | 0.342 |

| 38 | 0.102 | 681.9 | 732 | YL38S1.5EXTC1A | 0.178 | YL38D1.5EXXTC1A | 0.254 | YL38T1.5EXXXTC1A | 0.33 |

| 39 | 0.089 | 897.1 | 963.1 | YL39S1.5EXTC1A | 0.165 | YL39D1.5EXXTC1A | 0.241 | YL39T1.5EXXXTC1A | 0.317 |

| 40 | 0.079 | 1152 | 1237 | YL40S1.5EXTC1A | 0.155 | YL40D1.5EXXTC1A | 0.231 | YL40T1.5EXXXTC1A | 0.307 |

Challenges in Design and Production

Material Selection: Choosing the right insulation materials is crucial. Common materials include ETFE, PFA, and FEP, each offering unique properties but also requiring careful consideration of performance under high temperatures and frequencies.

Layer Adhesion: Ensuring strong adhesion between insulation layers is vital to prevent delamination during operation, which can lead to failure.

Manufacturing Complexity: The production process for triple insulated Litz wire is more intricate than for simpler wire types, necessitating specialized equipment and precise process control.

Cost Implications: The increased complexity and higher-quality materials can lead to higher production costs, necessitating a balance between performance and affordability.

Key Considerations for Users

Electrical Performance: Users must assess whether the enhanced electrical isolation and reduced losses justify the investment in triple insulated Litz wire.

Safety Requirements: For applications in sensitive environments (e.g., medical or aerospace), the increased safety from additional insulation can be a deciding factor.

Long-Term Reliability: The durability and reduced maintenance needs offered by triple insulated designs can lead to cost savings over time.

Advantages of Triple Insulated Litz Wire

Superior Electrical Performance: The three layers of insulation provide excellent electrical isolation, drastically lowering energy losses in high-frequency applications.

Enhanced Safety: Thicker insulation layers significantly decrease the risk of short circuits and electrical failures, making it a safer choice for demanding applications.

Extended Equipment Lifespan: The reliability of triple insulated Litz wire contributes to a longer operational lifespan for devices, ultimately reducing replacement and repair costs.

Disadvantages and User Perspectives

While there are several advantages, users must also consider some potential disadvantages:

Increased Cost: The complexity of production and high-quality materials can lead to a higher price point.

Reduced Flexibility: The additional insulation may decrease the wire’s flexibility, making it less suitable for applications requiring frequent bending.

Weight Considerations: The added insulation can increase the overall weight of the wire, which may not align with lightweight design requirements in certain applications.

Despite these drawbacks, users often choose triple insulated Litz wire for its superior performance in specific applications, particularly where efficiency and safety are paramount.